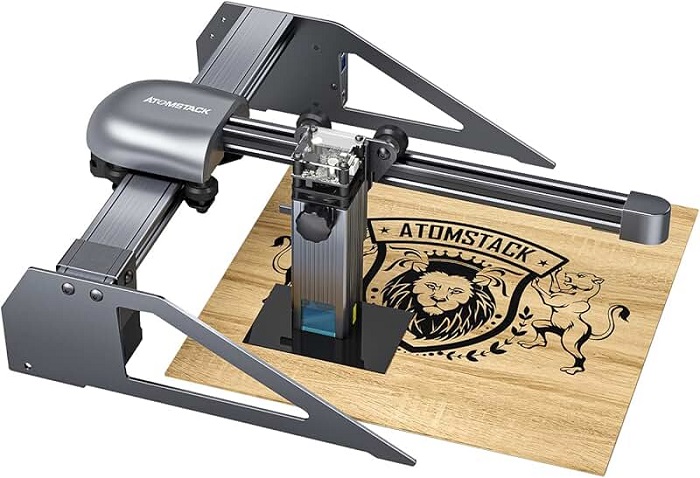

The rapid development of personal fabrication tools over the past decade has made formerly industrial-grade technologies accessible to hobbyists, artists, engineers, and small businesses. Among the most notable innovations is the laser engraver—particularly the diode-based models that balance affordability, portability, and precision. Atomstack, a prominent manufacturer in this space, has emerged as a key player offering accessible laser systems suitable for a wide range of applications.

From a technological standpoint, Atomstack machines rely on semiconductor diode lasers, typically operating at wavelengths around 445–455 nm (blue light). This type of laser, while not as powerful as CO₂ or fiber lasers, offers several advantages: compact size, energy efficiency, and a lower cost of ownership. When properly focused, these lasers are capable of engraving or cutting wood, leather, plastics (e.g., acrylic), paper, and anodized metals.

One of the most discussed aspects of Atomstack models is their use of fixed-focus laser modules. This design choice simplifies the focusing process—users only need to adjust the Z-axis (height) of the laser head rather than recalibrate the lens manually for every material. In many models, the laser modules deliver around 5W to 20W of optical power, with newer dual-diode combined modules pushing the upper boundary. The ability to concentrate laser output in a narrow beam spot, often as small as 0.06 mm, enables precise, high-resolution engraving.

Atomstack also integrates advanced motherboard control systems, often running open-source or open-protocol firmware compatible with software like LaserGRBL and LightBurn. These platforms offer nuanced control over power, speed, dithering algorithms, and layering—enabling both novices and professionals to customize output for various surface types and project goals.

The safety systems embedded in newer Atomstack units have also improved significantly. Features such as emergency stop buttons, limit switches, and laser shielding enclosures reduce the risk of accidental exposure and allow for safer indoor operation. These additions reflect growing awareness around the need for responsible use of Class 4 laser devices.

Importantly, there is a growing community of makers and designers optimizing Atomstack devices for niche uses, such as PCB prototyping, leather tooling, and even grayscale photo etching. These communities frequently share configuration profiles, troubleshooting tips, and upgrades—reinforcing the open-source ethos that underpins much of the desktop fabrication ecosystem.

While price remains a key factor for many buyers, it’s worth noting that Atomstack’s performance often punches above its cost bracket. Prospective users looking to reduce entry costs can often find discounted prices via platforms offering exclusive atomstack coupon code deals. These promotions make it more feasible for schools, workshops, or individual creators to acquire advanced tools without straining their budgets.

As materials science continues to evolve, the compatibility of diode lasers with newer substrates—like laser-engraveable metal composites or pretreated polymers—will only expand the versatility of Atomstack machines. Meanwhile, ongoing improvements in beam shaping optics, firmware updates, and modularity (e.g., rotary attachments and air assist kits) position Atomstack products as future-proof tools for serious creators.

To conclude, Atomstack represents a confluence of precision engineering, affordability, and open hardware compatibility. While not without limitations—diode lasers still lag behind in raw cutting power compared to CO₂ or fiber options—their accessibility makes them ideal for rapid prototyping, custom product creation, and educational environments. With the right settings and an understanding of materials, users can produce results rivaling commercial-grade systems, especially when supported by offers such as an atomstack coupon code.

Leave a Reply